CONTACT US:

CEI Projects

Canfield Engineering & Integration continues to tackle challening projects and delivery to our customers. Here are just a few of our latest works and the approach our CEI team took to complete these tasks at the industry’s highest level.

The Ashton Company, INC

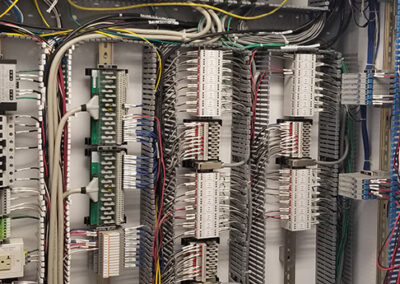

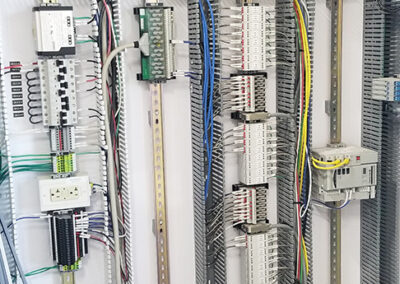

Provided Professional Engineering Services for a Lightning Protection System (LPS), Power Quality Meter (PQM), Power Study, PLC Programming and Integration as well as PLC control panel procurement. LPS work consisted of site visits, design drawings, specifications and coordination with the design/construction team. Design complied with NFPA-780. PQM entailed integration of new PQMs into existing control network and setup withing the RS Energy Metrix software. Power Study was performed in accordance with IEEE and utilized the ANSI method of short circuit analysis with a SKM model of engineer record design. PLC/HMI programming for (2) control panels, CP87A and CP19 and was integrated into Pima County’s Master PLC and HMI and the Wonderware/Enervista screens were updated per County standards. A second HMI system was updated using GE Enervista HMI including medium voltage switchgear off a medium voltage pad mount switch that was integrated. Procurement for control panels, CP87A and CP19 was provided including shop drawings, loop drawings, and a Factory Acceptance Test (FAT).

SXEW NFPA Support

ASARCO Ray Mine

Provided professional engineering services to support the effort to build and manage a maintenance program per NFPA. Site data was collected and entered in an interactive database. Pictures and maintenance reports were made accessible from the equipment within the database via hyperlinks which provided a visual view and access to most current maintenance reports. Recommendations, assistance with implementation, and database updates were provided for preventative maintenance throughout the site and followed up with corrective maintenance recommendations. Field data was coordinated with single line diagrams and tags were updated as needed.

RWRD TRW PQM Design and Procure

The Ashton Company, INC

Provided System Integration services to upgrade new IO and PWM data collection at the Tres Rios WWTF (TRW). Work consisted of site visits, design and software configuration along with coordination between Pima County and Ashton. Project included existing plant integration with verification of current and potential transformers and the existing Wonderware application. This was a follow up phase to update existing PQM’s that were not working correctly along with design to add IO and checkout between field, PLC’s and SCADA.

Dignity Generator Support PLC Redundancy

DP AIR

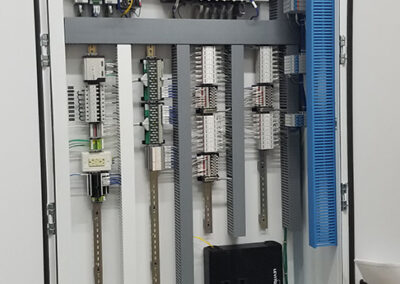

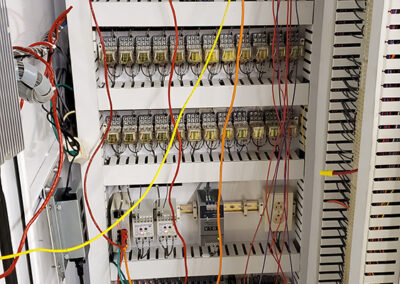

Performed design, fabrication and programming services to provide a more robust and reliable control system. Existing Schneider Quantum PLC was no longer supported by the manufacturer and was upgraded to a Schneider M580 PLC in a separate rack with redundant processor and power supplies. Entire system was recommissioned. PLC panel design drawings were updated, PLC was converted, OIT was upgraded to Wonderware, procurement and fabrication of a new PLC rack was provided and commissioning was performed.